Wet Blast Pots

Clemco’s Wetblast FLEX all-in-one wet blasting system helps minimize job site blast dust during high-performance blasting. Wet abrasive blasting applications include removing paints, industrial coatings, and other substances from a variety of surfaces, including wood and metal. In these systems, dust created and emissions are significantly reduced because the water suppresses ambient dust. Minimized dust increases operator visibility and safety. Wet blasting provides proper surface preparation for adhesion of subsequent coatings and in some cases a final finish.

The FLEX takes the proven technology of Clemco blast pots and provides maximum dust suppression while maintaining the convenience and simplicity not found in traditional slurry systems. With the FLEX system, the water and abrasive are not mixed until after the abrasive leaves the wet blaster. This means you don’t have to worry about emptying a pot of a messy water/abrasive mix.

Because the water and abrasive blast media are separated until blasting, you have options. You can either position the water injector at the base of the blast pot or at the nozzle. When the injector is attached at the nozzle, you can adjust the water/abrasive media mix at any time. Another benefit to this system is you can dry blast with FLEX—simply remove the injector and turn off the air pump.

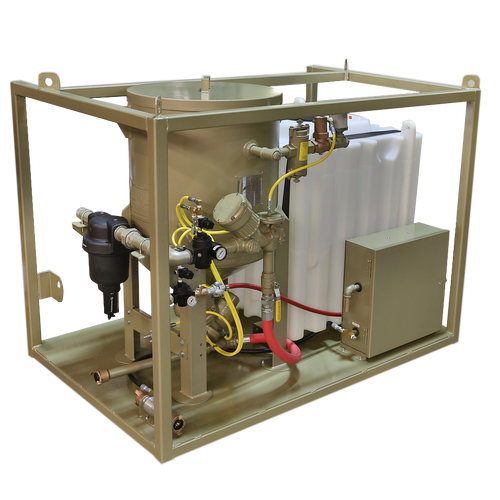

Clemco Wetblast FLEX systems include a 6 cubic-foot-capacity blast pot, 120-gallon water storage tank, and pump module mounted on a portable framed platform. They are also available as either a base Unit or as a Package. Standard systems operate from 50 to 120 psi. Low pressure (LP) systems with an extended operational range from 5 to 120 psi are also available.

Flex operation is simple:

- Simply fill the blast pot with abrasive and the water tank or connect to a municipal water supply. Adding rust inhibitors is optional.

- Connect compressed air, adjust metering valve, blast pressure, and water pressure.

- A single air connection supports all pneumatic equipment.

Clemco’s Wetblast FLEX is ideal for contractors because this easy-to-use, portable all-in-one wetblasting system fits in the back of most full-size pick-up trucks.

Wet Blast Pots

Clemco’s Wetblast FLEX all-in-one wet blasting system helps minimize job site blast dust during high-performance blasting. Wet abrasive blasting applications include removing paints, industrial coatings, and other substances from a variety of surfaces, including wood and metal. In these systems, dust created and emissions are significantly reduced because the water suppresses ambient dust. Minimized dust increases operator visibility and safety. Wet blasting provides proper surface preparation for adhesion of subsequent coatings and in some cases a final finish.

The FLEX takes the proven technology of Clemco blast pots and provides maximum dust suppression while maintaining the convenience and simplicity not found in traditional slurry systems. With the FLEX system, the water and abrasive are not mixed until after the abrasive leaves the wet blaster. This means you don’t have to worry about emptying a pot of a messy water/abrasive mix.

Because the water and abrasive blast media are separated until blasting, you have options. You can either position the water injector at the base of the blast pot or at the nozzle. When the injector is attached at the nozzle, you can adjust the water/abrasive media mix at any time. Another benefit to this system is you can dry blast with FLEX—simply remove the injector and turn off the air pump.

Clemco Wetblast FLEX systems include a 6 cubic-foot-capacity blast pot, 120-gallon water storage tank, and pump module mounted on a portable framed platform. They are also available as either a base Unit or as a Package. Standard systems operate from 50 to 120 psi. Low pressure (LP) systems with an extended operational range from 5 to 120 psi are also available.

Flex operation is simple:

- Simply fill the blast pot with abrasive and the water tank or connect to a municipal water supply. Adding rust inhibitors is optional.

- Connect compressed air, adjust metering valve, blast pressure, and water pressure.

- A single air connection supports all pneumatic equipment.

Clemco’s Wetblast FLEX is ideal for contractors because this easy-to-use, portable all-in-one wetblasting system fits in the back of most full-size pick-up trucks.