Wetblast Tools That Convert Dry-Blast Machines into Wetblast Systems

By on Jan 30th 2023

Wetblast Tools That Convert Dry-Blast Machines into Wetblast Systems

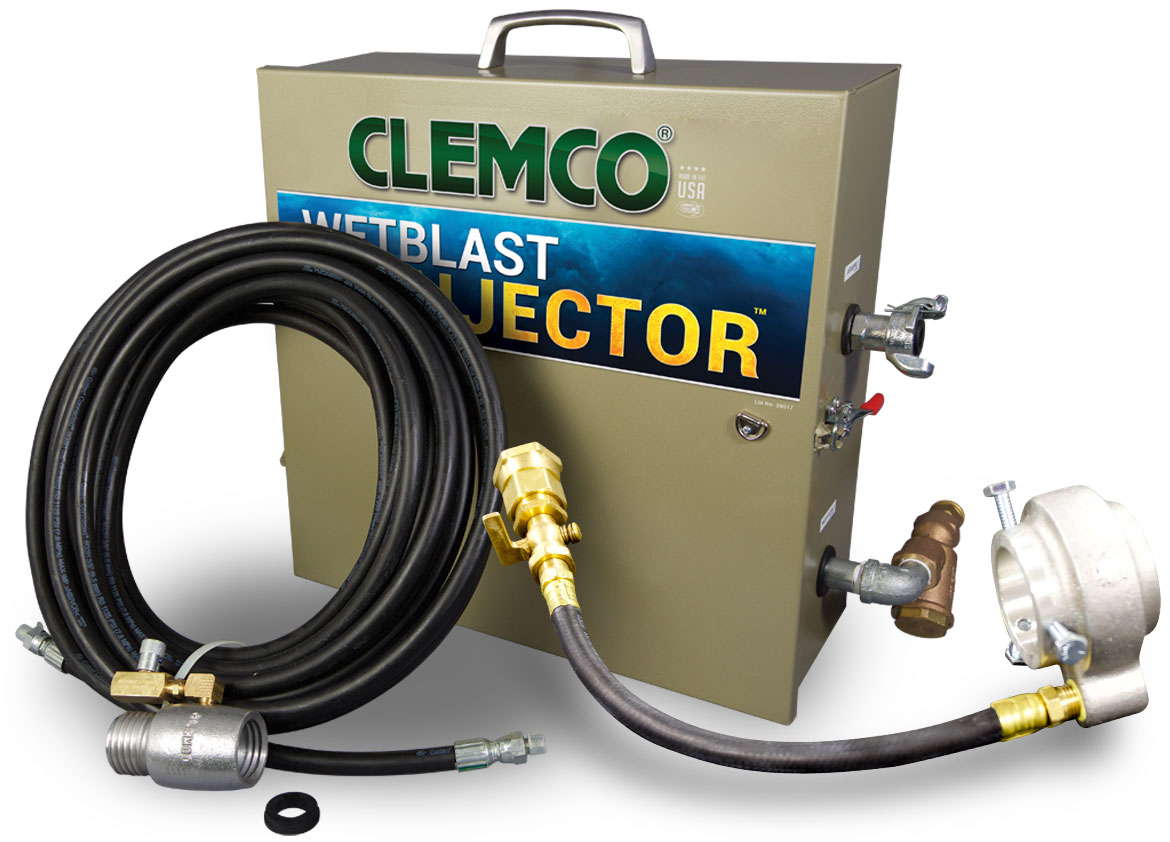

Wetblast Injector System and Wetblast Attachment

You have dry-blast equipment that you rely on day in and day out, but you also miss out on jobs because of your dry-bast equipment can't wetblast. Perhaps you're not ready to invest in a full-scale wetblast system--but you'd sure like those extra jobs. Clemco has two solutions:

- Wetblast Injector System - Converts a dry-blast machine into a high-performance wetblast system.

- Wetblast Attachment - Compact conversion tool for occasional wetblasting.

Wetblast Injector System

The only conversion kit on the market that modifies a dry-blast machine into a high-production wetblast system.

High-Performance Wetblast Capabilities

Take on any job that a full-scale wetblast system can:

- Water-adjustment controls at operator's fingertips for precise fine-tuning of water flow into the blast stream.

- Water and media mix before entering

the blast nozzle, which

helps:

- Maintain high media exit velocity, ensuring efficient blasting.

- Fully saturate media with water, improving dust suppression for visibility and regulatory compliance.

- Ensure thorough wash down of blast surface for a contaminant-free finish.

Easy to Use

Quickly and easily available for any job:

- Compact and lightweight.

- Easy to transport and store because it takes up little space.

- Simple setup. Connect to:

- A compressed-air source.

- A pressurized, municipal water source such as an outdoor spigot or a kitchen faucet.

- Or use the water pump that comes standard with the Wetblat Injector to retrieve water from a storage tank.

Application Versatility

Switch back to dry blasting with the twist of a knob:

- Take on wet- and dry-blast jobs.

- No need to buy a second piece of equipment. The Wetblast Injector converts the dry-blast pot you already have into a complete wetblast system.

Compliance

Allows you to comply with environmental safety regulations and safeguard your operators from exposure to hazardous dust:

- Suppresses dust generated during abrasive blasting, reducing operator, co-worker, and bystander exposure to hazardous dust.

- Helps satisfy urban dust-abatement requirements when blasting in metropolitan areas.

- Decreases dust-containment and cleanup costs, saving you time and expense.

Specifications - Six Configurations

One Operator

- 1-1/4" nozzle adaptor

- 50 mm nozzle adaptor - 1-1/4" entry

- 50 mm nozzle adaptor - 1" entry

Two Operators

- 1-1/4" nozzle adaptor

- 50 mm nozzle adaptor - 1-1/4" entry

- 50 mm nozzle adaptor - 1" entry

Wetblast Attachment

For contractors who don't wetblast every day--but need to be ready for wetblast jobs.

Application Versatility

Wetblast capabilities quickly installed on your dry-blast machine at a low upfront cost.

- Water-adjustment valve at operator's fingertips for adjusting water flow into media after it exits the blast nozzle.

- Best suited for contractors who primarily dry blast but need wetblast capabilities in their back pocket.

Easy to Use

Quickly and easily ready for wetblast jobs:

- Simple to install and detach.

- Compact and lightweight. Could fit in your toolbox. Easy to store.

- Simple, low-maintenance design.

- Does not require an air-supply.

Compliance

Allows you to comply with environmental safety regulations and safeguard your operators from exposure to hazardous dust:

- Suppresses dust generated during abrasive blasting, reducing operator, co-worker, and bystander exposure to hazardous dust.

- Helps satisfy urban dust-abatement requirements when blasting in metropolitan areas.

- Decreases dust-containment and cleanup costs, saving you time and expense.

Requirements for Operation

- Access to a pressurized, municipal water source such aas an outdoor spigot or a kitchen faucet.

- Can also be connected to a water storage tank, but you need to supply the water pump.

Specifications - One Configuration

- Use with all standard nozzles except CT nozzles.

- Includes water ring, water-adjustment valve, flexible hose, and garden-hose fitting.