How Can You Easily Determine the Pipe Size on Your Classic Blast Machine?

By on Sep 6th 2019

Clemco manufactures classic blast machines in model sizes ranging from 0.5 cuft to 20 cuft, in both portable and stationary options. All models of blast machines are equipped with industrial-quality valves, piping, and fittings that maximize airflow and productivity while minimizing energy use. Given the environment in which these blast machines operate, normal wear is common, and at some point, you will need to replace individual components to maintain productive blasting.

Why Pipe Size is Important

While all parts are manufactured to the same standard, they are not all equal, and it’s essential to choose the proper components for your blast machine. The correct parts are dictated by not just whether your machine is classic or contractor style, but also the machine model and the size of its piping.

Remote control systems are an OSHA-required safety device for all blast machines. R/C systems have valves matched in size to the blast machine piping, so having this information on hand is critical if you need to replace your inlet valve, for example, or are buying TLR Remote Controls separately.

The inlet valve is responsible for the inflow of air (from your air compressor) to pressurize the blast pot and is controlled by the R/C system (as is the outlet valve). If you have a contractor-style machine, the inlet valve and outlet valve are a two-in-one unit, so the following information is not applicable to your setup.

How to Determine Pipe Size

If you have one of the smallest blast machines available, or one of the largest, determining your pipe size is straightforward. 0.5 cuft and 1 cuft blast machines can only use the 0.5” inlet valve. Similarly, the 2 cuft blast machine is only available with 1” piping, and anything over 10 cuft has 1.25” piping. However, it’s the machines in between that are available with options, and therefore, you may not know what size the piping is.

The 6 cuft blast machine, for example, is the most popular blast machine that Clemco manufactures, and is available with both 1” and 1.25” piping. Knowing what you have is vital to ensure you get the appropriate R/C components.

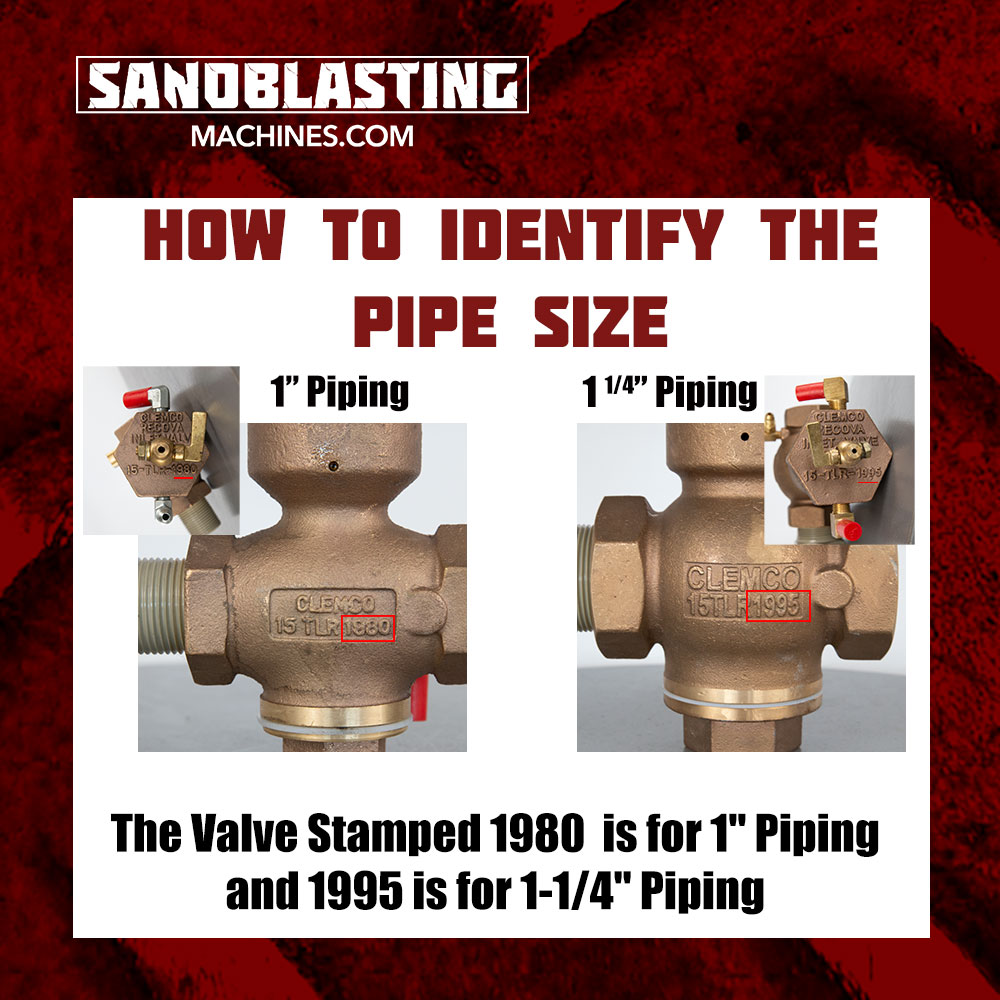

While the 1” inlet valve is smaller than the 1.25” inlet valve, it’s challenging to determine size unless you have something to compare it to. Fortunately, there is a very easy way to determine whether your machine has 1” or 1.25” piping just by looking at the inlet valve.

Each valve is stamped with certain information, including some numbers. If your Clemco inlet valve is stamped with “1980,” your blast machine has 1” piping. If the valve is stamped with “1995,” your machine has 1.25” piping.

Once you know your pipe size, you can buy the right R/C system and components. If you have a small blast pot with 0.5” piping, you need the TLR 50 remote controls. TLR 100 controls are for machines with 1” piping, and TLR 300 controls have 1-1/4” piping.