Choosing the Right Blast Nozzle and Compressed-Air Equipment

By on Mar 9th 2021

Increase productivity and decrease downtime.

Tips for choosing the best air compressor, air line, blast nozzle, and air-preparation equipment for your next blasting job. This is the first article in a three-part series.

This article gives an overview of the equipment needed to supply, deliver, and prepare enough moisture-free compressed air for a typical abrasive blasting job.

It is the first article in a three-part series about abrasive blasting equipment. The second article covers blast machines and their major components, and the third article looks at safety equipment and safety practices.

However, before choosing equipment or establishing safety procedures, evaluate the target surface and the worksite environment, perform a job hazard analysis, and assess the goals of the job.

1. Air Compressors

Use an air compressor that is large enough to produce the air volume and pressure required to adequately and safely pressurize the blast machine, convey abrasive to the blast nozzle, provide breathing air, and operate valves and accessories.

To determine the compressor size needed for a job, add the air requirements of all the equipment that the compressor will supply and then add a 50% reserve, which will be needed to keep productivity high as the blast nozzle wears—and it will wear.

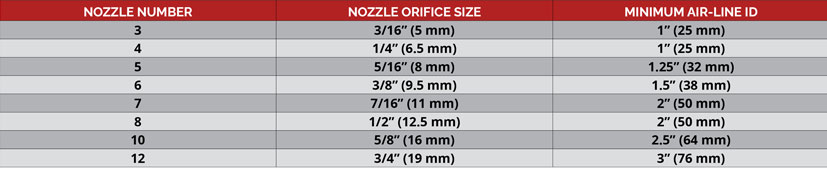

To maintain peak air supply, the smallest internal diameter (ID) of the compressor air outlet should be at least four times the size of the nozzle orifice.(See Table 1.)

TABLE 1: Minimum Compressor Air-Line Diameter

2.Blast Nozzles

Replace a blast nozzle after its orifice is worn to 1⁄16” (1.5 mm) larger than its original size. A worn nozzle not only wastes air, but also may lower productivity and even cause injury if the liner fails. Carbide nozzles—tungsten, silicon, and boron—are the most popular for the majority of blasting applications because of their longevity.

See what types of Clemco blast nozzles are offered by SandBlastingMachines.com,

3. Air Lines

The air-line ID should be as large as possible and at least four times the nozzle orifice size. This principle applies to air lines up to 100 ft. With longer hoses, especially longer than 200 ft., check the air pressure at the blast machine while blasting to determine if the air-line ID is sufficient.

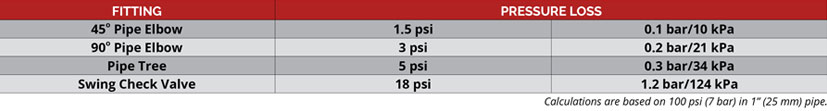

Air flows best through unrestricted fittings and straight air lines, so lines should be laid out in as short a length and with as few bends as possible to reduce pressure loss.(See Table 2.)

TABLE 2: Approximate Pressure Loss Caused by Common Fittings

4. Air-Preparation Equipment

Moisture in the compressed-air supply can travel into the blast machine. If this occurs, abrasive may clump, which can cause stoppages in abrasive flow. Air-preparation equipment helps prevent these stoppages.

Depending on the humidity level of the air where operators are working, varying levels of air-preparation equipment may be needed. Coalescing filters provide the minimum level of moisture removal.

They collect some of the water vapors that have formed into small droplets before the droplets enter the air filter. Aftercoolers cool air to condense even more moisture and then trap the moisture before it is conveyed to the blast machine. Air dryers are the most effective option for removing moisture and also oil from air.

For all of your Clemco Abrasive Blast Equipment needs, be sure to visit us at Sandblasting Machines, with Free Shipping on Orders $75+.