Reliable, Simple to Maintain, Easy to Use Pulsar Plus Blast Cabinets

By on Feb 8th 2024

You spoke. We listened.

After talking with customers and distributors all over the country to understand what they need in a blast cabinet, Clemco created the Pulsar® Plus Line of Blast Cabinets. These high-production cabinets give customers what they really need:

- Reliable and consistent results.

- Simple maintenance.

- Ease of use.

- Seventeen ergonomic and state-of-the-art features that boost productivity.

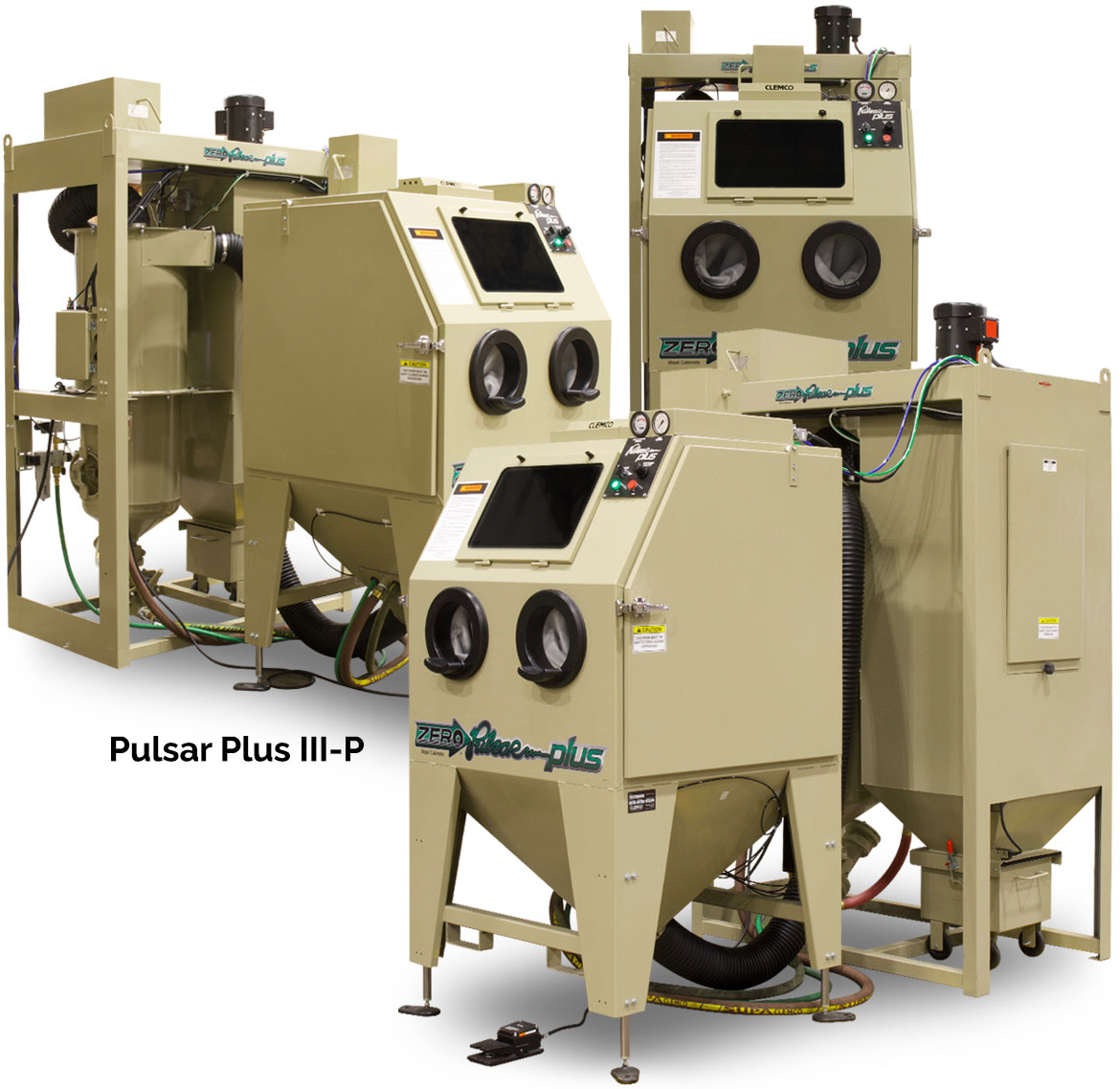

- Six models to choose from: suction and pressure.

- A detached power module that allows for flexible blast-system configurations into awkward or tight workspaces. Ideal for cell manufacturing.

- Low cost of ownership.

- Quick return on investment.

Clemco’s ZERO® brand Pulsar Plus Blast Cabinets have reimagined the possibilities of cabinet abrasive blasting. They make abrasive blasting with a cabinet safer, more efficient, and more profitable—while providing consistent, repeatable results that help you and your team get more jobs done on time and on budget.

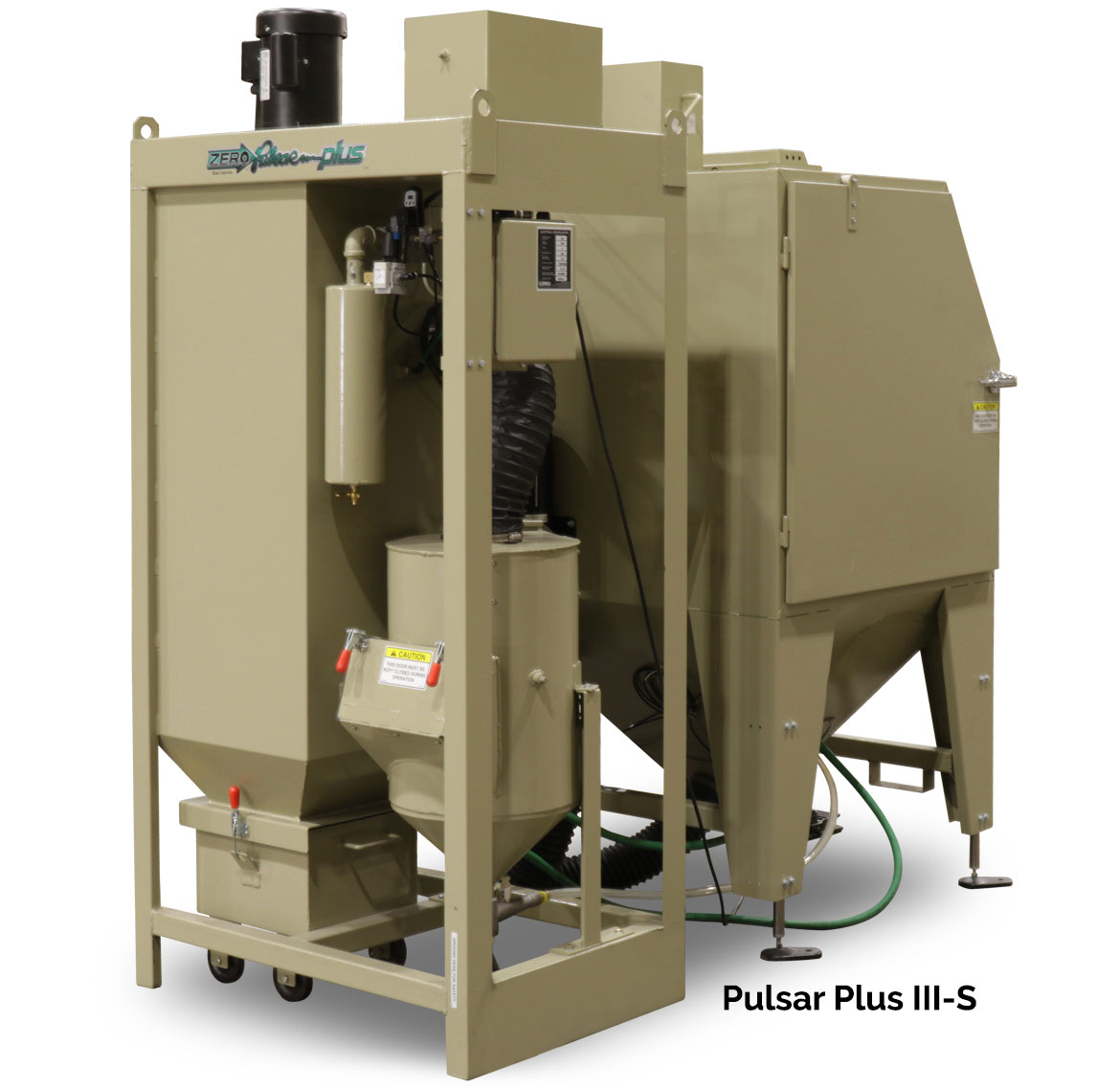

Two Suction Cabinets: Pulsar Plus III-S and VI-S

Suction Cabinet Advantages

These high-production suction cabinets are designed to function with lower air volume. They are equipped with the industry-leading BNP® Blast Gun, which sets the standard for efficiency and productivity in cabinet abrasive blasting.

Specifications

- Pulsar Plus III-S

36”W x 35”D x 37”H

300 CFM reclaimer and 300 CFM dust collector - Pulsar Plus VI-S

50”W x 39”D x 37” H

600 CFM reclaimer and 600 CFM dust collector

Two Speciality Suction Cabinets: Pulsar Plus 55-S and III-S6

Speciality Suction Cabinet Advantages

Pulsar Plus 55-S— The most compact Pulsar Plus Cabinet. It is fixed height and the power module is attached. Pulsar Plus III-S6— For floor plans that require a small footprint, yet the extra power of a 600 CFM reclaimer and a 600 CFM dust collector.

Specifications

- Pulsar Plus 55-S

42”W x 23”D x 30”H

300 CFM reclaimer and 300 CFM dust collector - Pulsar Plus III-S6

36”W x 35”D x 37”H

600 CFM reclaimer and 600 CFM dust collector

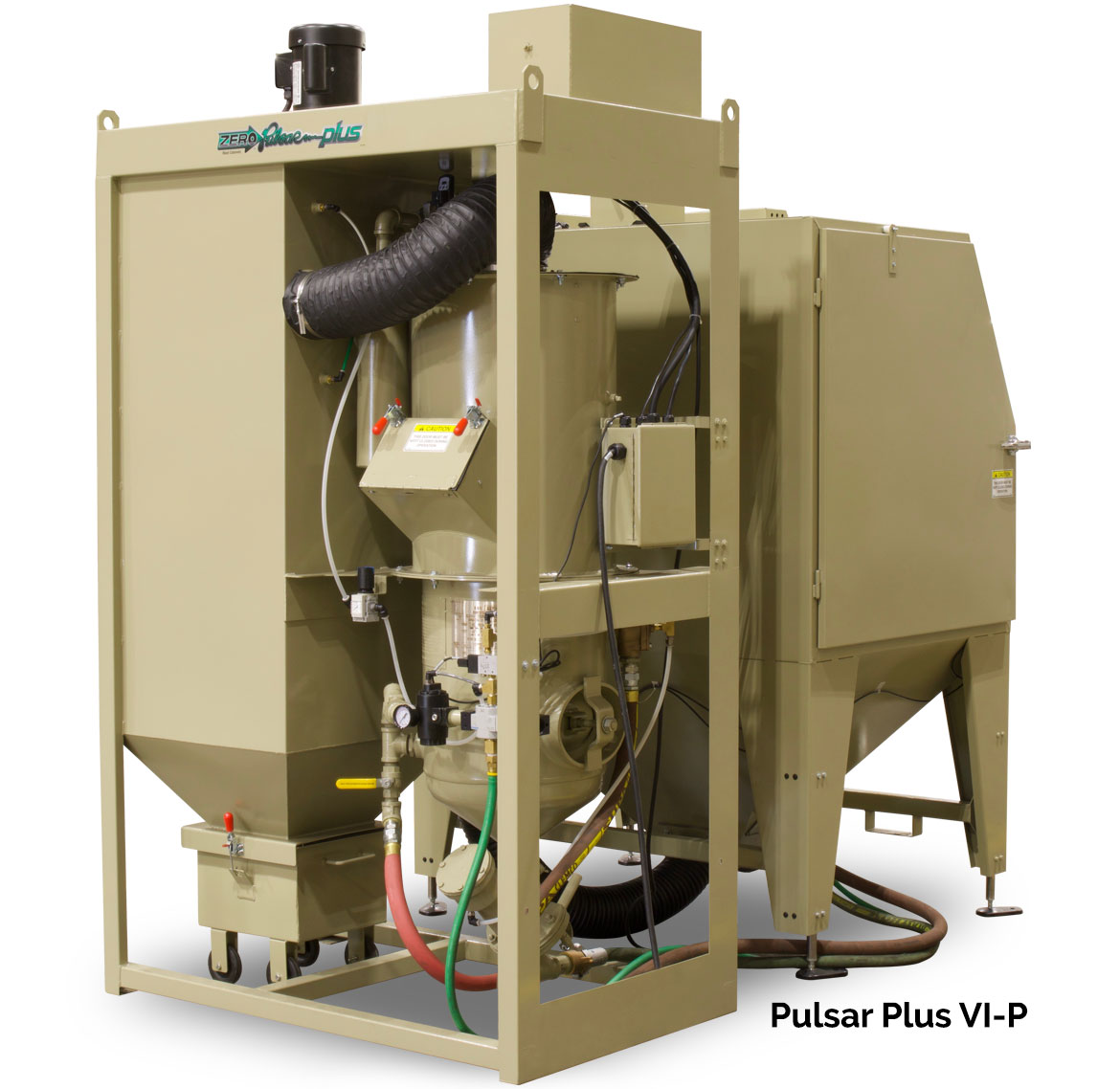

Two Pressure Cabinets: Pulsar Plus III-P and VI-P

Pressure Cabinet Advantages

For high-production applications, pressure cabinets clean three to four times faster than suction cabinets. They require high volumes of compressed air to maintain this production rate.

Specifications

- Pulsar Plus III-P

36”W x 35”D x 37”H

300 CFM reclaimer and 300 CFM dust collector - Pulsar Plus VI-P

50”W x 39”D x 37” H

600 CFM reclaimer and 600 CFM dust collector

Pulsar IX Suction and Pressure Blast Cabinets

Pulsar IX Cabinets are Clemco’s largest standard, single-chamber blast cabinets. Note that they do not have all of the standard features of a Pulsar Plus Cabinet.

Dimensions

- Cabinet – 61″W x 57.5″D x 87″H

- Working Chamber – 55.5″W x 50.5″ D x 45″H

- Power Module – 50″W x 62″ D x 93”H

Pulsar 3-D Suction Blast Cabinet

For small work pieces and production parts, blasting with the Pulsar 3D leaves them with a consistent finish. This versatile cabinet is ideal for tight workspaces with intermittent blasting needs.

Dimensions

- Total Footprint – 40.25″W x 47″D x 67.5″H

- Working Chamber – 24″W x 18″ D x 19″H

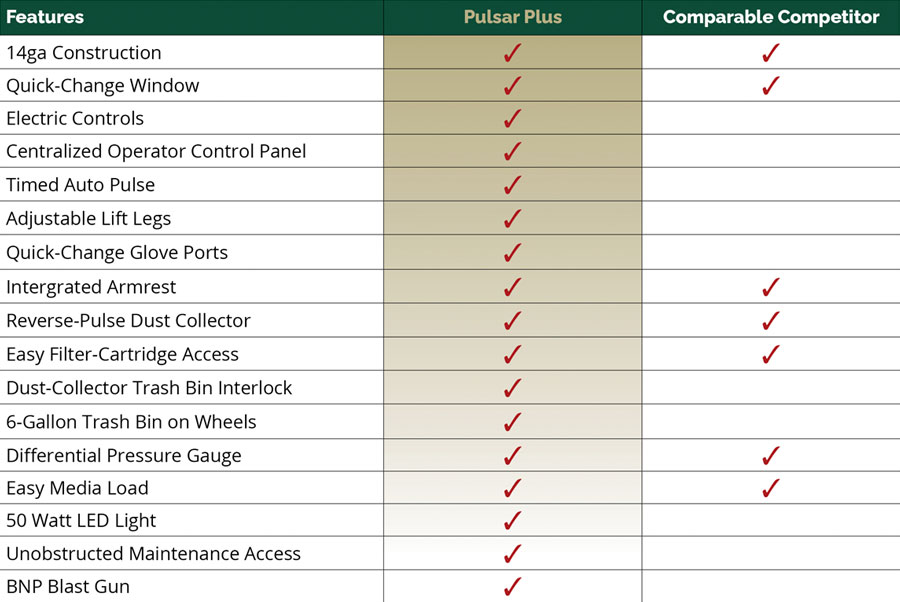

Seventeen Ergonomic and State-of-the-Art Features

More Than Our Competitors

Ergonomic Design

Electric, Height-Adjustable Lift Legs

- Problem: Operators frequently work in uncomfortable positions, some even standing on boxes.

- Solution: Operators of varying heights now can work comfortably, which can improve productivity, reduce injuries, and improve work quality.

Quick-Change Glove Ports with Integrated Armrests

- Problem: Operators prefer to have their own set of gloves; however, glove change-out time makes dedicated gloves impractical.

- Solution: Quick-change glove ports are easy and fast to install, so operators can have a dedicated set of gloves. Integrated armrests help operators stay comfortable during long or demanding shifts.

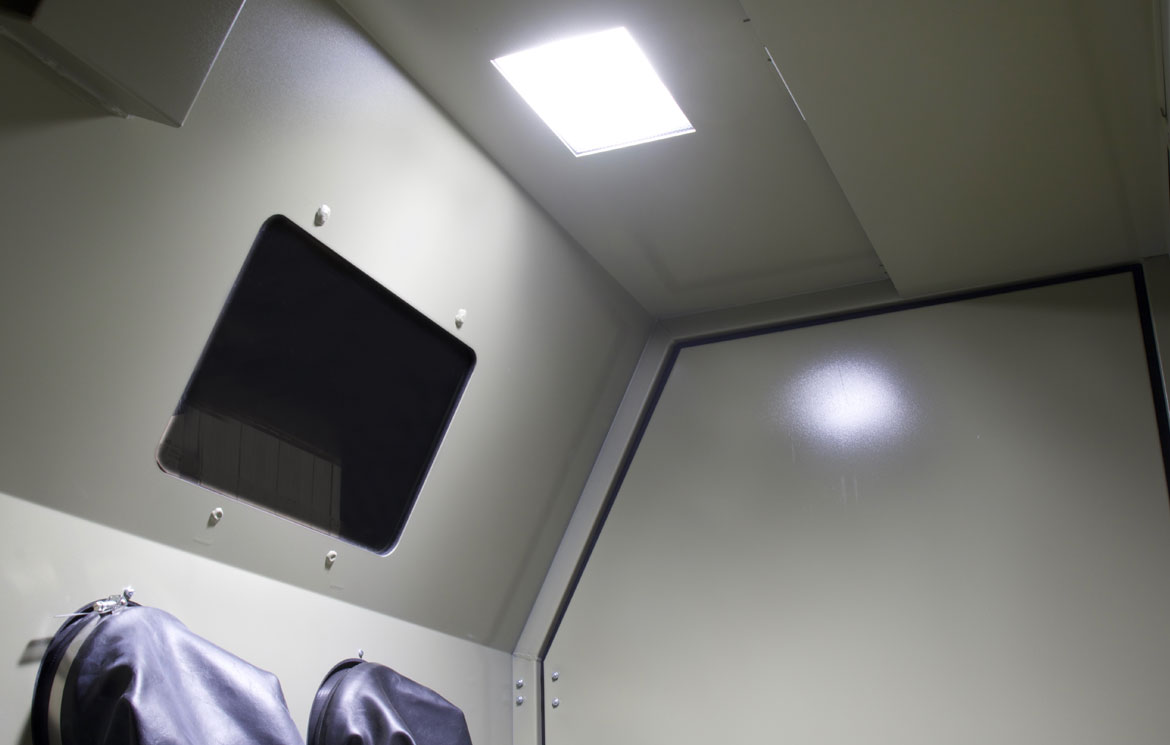

50 Watt LED Lights

- Problem: Poor lighting reduces visibility, which contributes to inconsistent blasting quality and decreased productivity.

- Solution: Abundant lighting is one of the simplest fixes for improving operator efficiency. State-of-the-art, 50-watt LED lights outshine even higher-wattage florescent and incandescent lights.

Gauges and Controls Are Simple to Monitor and Adjust

Centralized Operator Control Panel

- Problem: Operators cannot effectively monitor a cabinet’s operations because controls and gauges are spread out, inconveniently located—or nonexistent on lower quality cabinets.

- Solution: The panel’s centralized location lets operators know at a glance whether the cabinet is operating at peak efficiency and allows them to make immediate adjustments.

Electric Control Circuit

- Problem: Customers often are unaware that dirty air and air leaks cause control circuit failures in their cabinets.

- Solution: Electric controls eliminates air-related failures in control circuits. Eliminates plumbing complexity.

Safe and Efficient Reverse-Pulse Dust Collector

1-HP Exhauster Motor

- Problem: An improperly maintained filter cartridge reduces air flow through the recovery system.

- Solution: The 1-HP exhauster motor ensures optimal media recovery and visibility. It helps maintains an efficient, closed dust-collection system.

Timed Auto Pulse

- Problem: The pulse frequency for cleaning dust-collector cartridges in manual-pulse cabinets is often ineffective because operators often do not actuate the pulse at appropriate intervals.

- Solution: The filter cartridge is pulsed at timed intervals, ensuring proper cleaning of the cartridge. This maximizes filter life, helps maintain a proper media mix, and ensures consistent parts coverage and high productivity.

Straightforward Dust-Collector Maintenance

Differential Pressure Gauge

- Problem: Operators do not know when the dust-collector filter cartridge needs replacement.

- Solution: In just a glance, operators can see if the cartridge needs to be replaced. A properly maintained cartridge promotes visibility in the cabinet and ensures proper media flow to the recovery system.

Side-Access Filter Cartridge Door and Twist-Lock Filter Cartridge

- Problem: Dust collector maintenance is a low priority for many operators. The filter cartridge is difficult to access and replace.

- Solution: Uncomplicated access speeds up routine maintenance and helps prevent accidental dust release.

6-Gallon Dust Container on Wheels with Interlock

- Problem: The dust-collector waste container frequently is damaged or incorrectly connected.

- Solution: Interlocks ensure the dust container is securely connected to the dust collector. This connection promotes recovery system efficiency and reduces dust in the work area.

Time-Saving Convenience and Safety

Media Load Chute

- Problem: The area around reclaimers generally has media on the floor.

- Solution: Simplified media loading helps eliminate waste and safety hazards caused by spilled media.

Multi-Connection Port and Adaptor

- Problem: Installing and troubleshooting pneumatic systems is time-consuming, and can disrupt productivity.

- Solution: A single adaptor simplifies securing electric connections between the control panel and power module. It contains all electric connections from the power module and plugs into the multi-connection port.

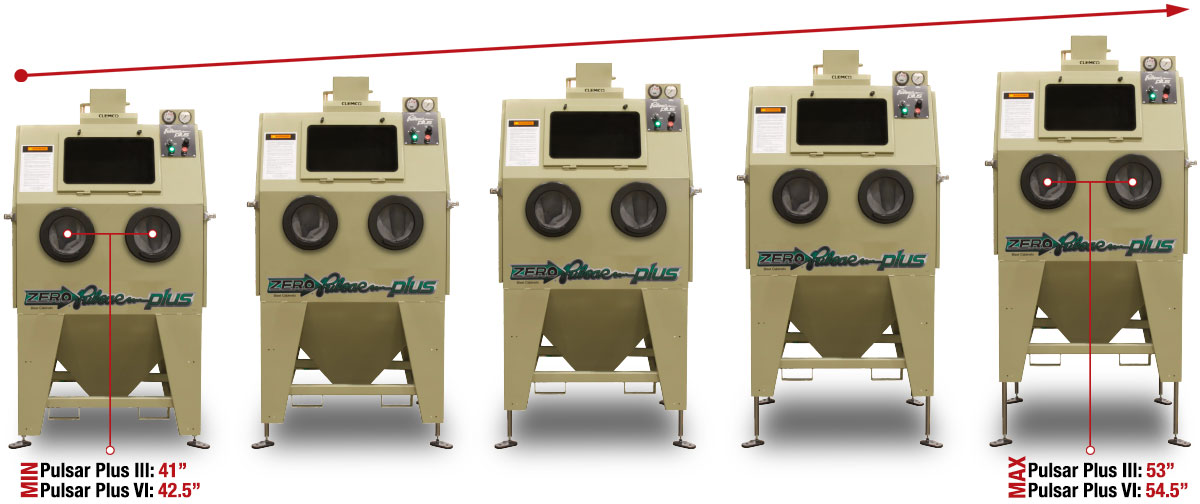

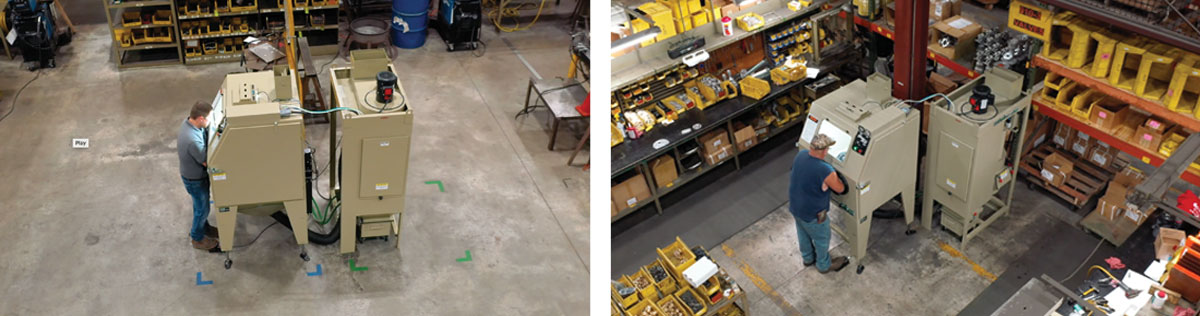

Adaptable, Common-Sense Design

Pulsar Plus Cabinets can be configured to meet your space needs.

Detached Power Module

- Problem: Space restriction often force facilities to purchase cabinets that fit in their space restrictions, but don’t meet all of their production needs.

- Solution: The power module’s compact design allows for flexible configuration with the blast cabinet, enabling the entire blast system to fit into awkward or tight workspaces in various work environments.

Unobstructed Access to Wear Parts

- Problem: Difficult to reach wear components increase downtime when they need replacement.

- Solution: Clear, quick access to common wear parts, such as the reclaimer inlet adaptor and the pulse control valve, dramatically decreases maintenance downtime.

Unobstructed Access to Components

- Problem: Switching between different media is time-consuming.

- Solution: Unhindered access to the metering valve, pulse-pressure regulator, pulse timer, and outlet damper simplifies Pulsar Plus Cabinets’ capability to adapt to different media.