Plastic Media Blasting & Applications – Informative Guide

By on Jul 29th 2025

Blasting applications are essential processes used across industries for cleaning, stripping, and preparing surfaces, whether for repainting, refurbishing, or maintaining equipment and molds. Among the various abrasive media used in blasting, plastic media stands out as a particularly beneficial choice for industry professionals, offering significant operational advantages, cost savings, and environmental benefits.

Why Choose Plastic Media?

Plastic media blasting (PMB) is an advanced technique that utilizes engineered plastic particles to effectively remove coatings and contaminants without damaging underlying substrates. Unlike traditional abrasive media, plastic media is chemically inert, non-toxic, and recyclable, significantly enhancing operational efficiency and environmental support.

Key Advantages of Plastic Media:

- Cost Savings: Plastic media can be reused multiple times, drastically reducing overall media consumption and disposal costs.

- Operational Efficiency: It provides fast-acting stripping capabilities and maintains effectiveness over many cycles of use.

- Environmental Benefits: Being non-toxic and recyclable, plastic media reduces environmental impact compared to traditional blasting abrasives.

Types of Plastic Media: Exploring Their Uses and Benefits

At SandblastingMachines.com, we offer three main types of plastic media, each designed for specific applications and surface requirements:

Type II – Urea

Type II Urea media, which is Mil Spec approved (MIL-P-85891A), is known for its gentle yet effective stripping capabilities. It possesses a Barcol hardness of 54-62 and a MOHS scale rating of 3.5, allowing it to strip coatings without harming delicate surfaces.

- Aircraft component cleaning

- Automotive paint removal

- Surface preparation of composite materials

Urea media offers consistent particle size and static resistance, making it highly suitable for sensitive substrates such as aluminum, fiberglass, and other composite materials.

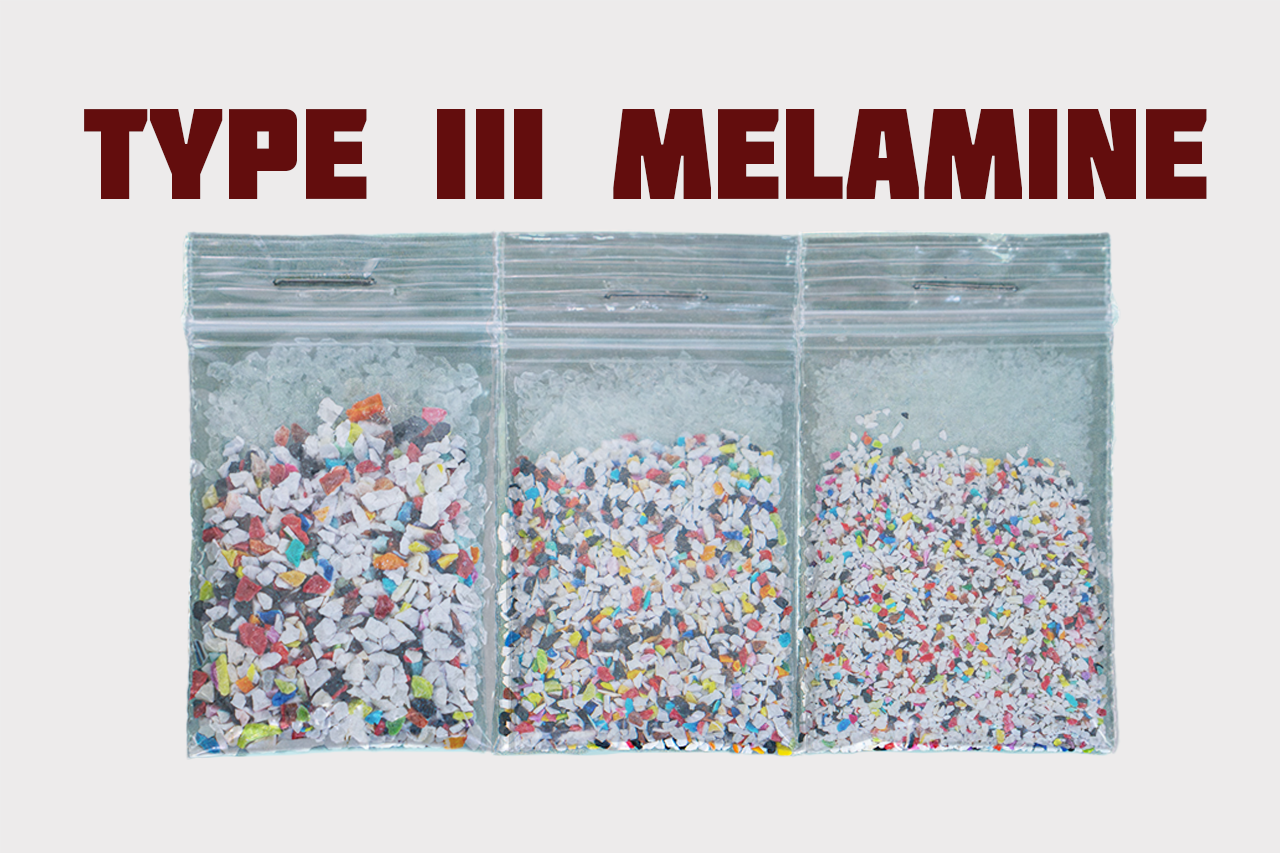

Type III – Melamine

Melamine media is characterized by its increased hardness, with a Barcol hardness range of 64-72 and a MOHS scale rating of 4.0. This enhanced hardness allows for more aggressive blasting compared to Urea, making it suitable for tougher coatings and contaminants.

- Mold cleaning

- Removing thicker coatings from automotive parts

- Preparation of steel and other durable surfaces

Due to its higher operational temperature threshold of up to 350°F, Melamine is ideal for high-temperature applications and more durable substrates.

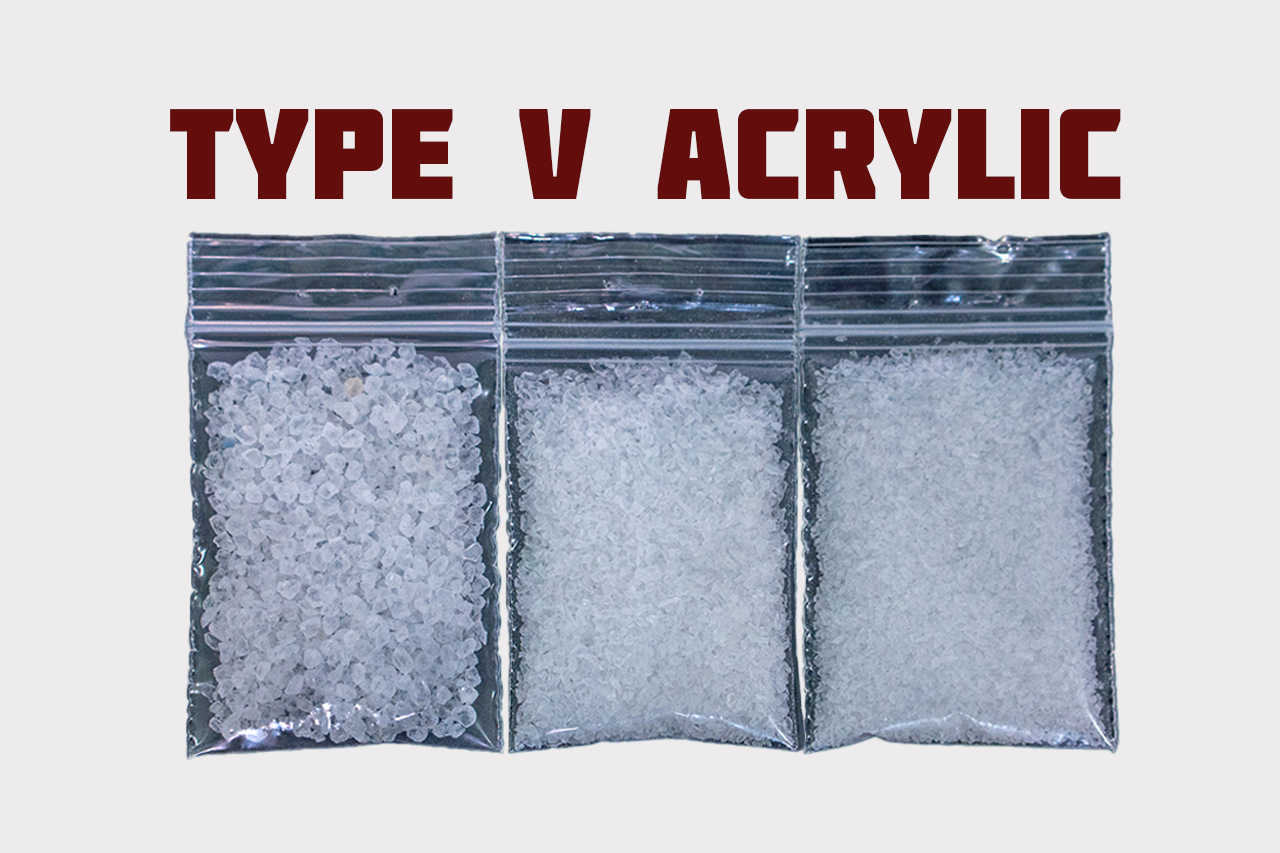

Type V – Acrylic

Type V Acrylic media, which meets MIL-P-85891A specification, is softer, with a Barcol hardness of 46-54 and a MOHS rating of 3.5. Its lower hardness and specific gravity (1.15-1.20 gms/cc) ensure minimal impact on sensitive surfaces while effectively removing coatings.

- Cleaning delicate aviation components

- Surface preparation of aerospace materials

- Gentle removal of coatings from aluminum and thin-gauge metals

Acrylic media operates effectively at temperatures up to 200°F, making it suitable for applications where heat sensitivity is a concern.

Conclusion: Why You Should Consider Plastic Media

Including plastic media into blasting operations provides manufacturers and industrial operators with substantial benefits that directly impact their operational efficiency, budget, and environmental footprint. Plastic media's recyclability significantly reduces waste and disposal costs, while its operational efficiency and gentle stripping action safeguard valuable substrates, extending the lifespan of critical components and tooling.

Industry professionals looking to optimize blasting operations should strongly consider the proven advantages of Type II Urea, Type III Melamine, and Type V Acrylic abrasive media. By choosing plastic media, businesses not only enhance their productivity but also actively contribute to sustainable and environmentally responsible operations.

Sources:

- Opti-Blast. Reusable and Recyclable Plastic Blast Media.

- Opti-Blast. Benefits of Reusing and Recycling OptiBlast Plastic Blast Media.

- AZoM. Plastic Media Blasting for Gentle Coating Removal.

- Opti-Blast. Standard Product Range.

- Opti-Blast. Recycling Plastic Blast Media.