MIL-P-85891A: Understanding the Military Specification for Plastic Media Blasting

By on Dec 8th 2025

In the world of aviation and military maintenance, precision in surface preparation is non-negotiable. Aircraft components, especially aluminum skins, composites, and thin-gauge metals, require a blasting media that can remove coatings without compromising structural integrity.

This is where MIL-P-85891A, the U.S. military specification for plastic blast media, sets the standard.

What Is MIL-P-85891A?

MIL-P-85891A is a formal U.S. Department of Defense specification that outlines the requirements for plastic media used in blast cleaning operations. The term “MIL-SPEC” signals that a product has been manufactured and tested to meet strict standards for:

- Material Composition

- Hardness and particle size

- Fracture characteristics

- Cleanliness and contamination limits

- Consistency across production batches

When a plastic media claims MIL-P-85891A compliance, it means it has passed rigorous testing to ensure predictable, safe, and repeatable performance. These are essential attributes when working on military and aviation assets.

Why This Specification Exists

Traditional mineral abrasives are too aggressive for many military and aerospace components. Even light over-profiling can distort thin metals or damage composite structures.

Plastic media was developed specifically to solve that problem. MIL-P-85891A ensures that the media:

- Removes coatings cleanly

- Protects the underlying substrate

- Maintains a controlled, predictable cut rate

- Does not contaminate or overheat sensitive materials

A specification like this exists because technicians cannot afford surprises when preparing critical parts for maintenance or overhaul.

Where MIL-P-85891A Media Is Used

Across all branches of the U.S. military and throughout the aviation industry, MIL-SPEC plastic media is used in applications such as:

- Stripping polyurethane and epoxy coatings from aircraft skins

- Cleaning wheels and brakes during refurbishment

- Removing coatings during engine component overhauls (non-critical surfaces)

- Preparing composite parts without fiber damage

- Removing powder coatings or paint without altering part geometry

The appeal of plastic media is simple: it is strong enough to remove stubborn coatings but gentle enough to preserve delicate surfaces.

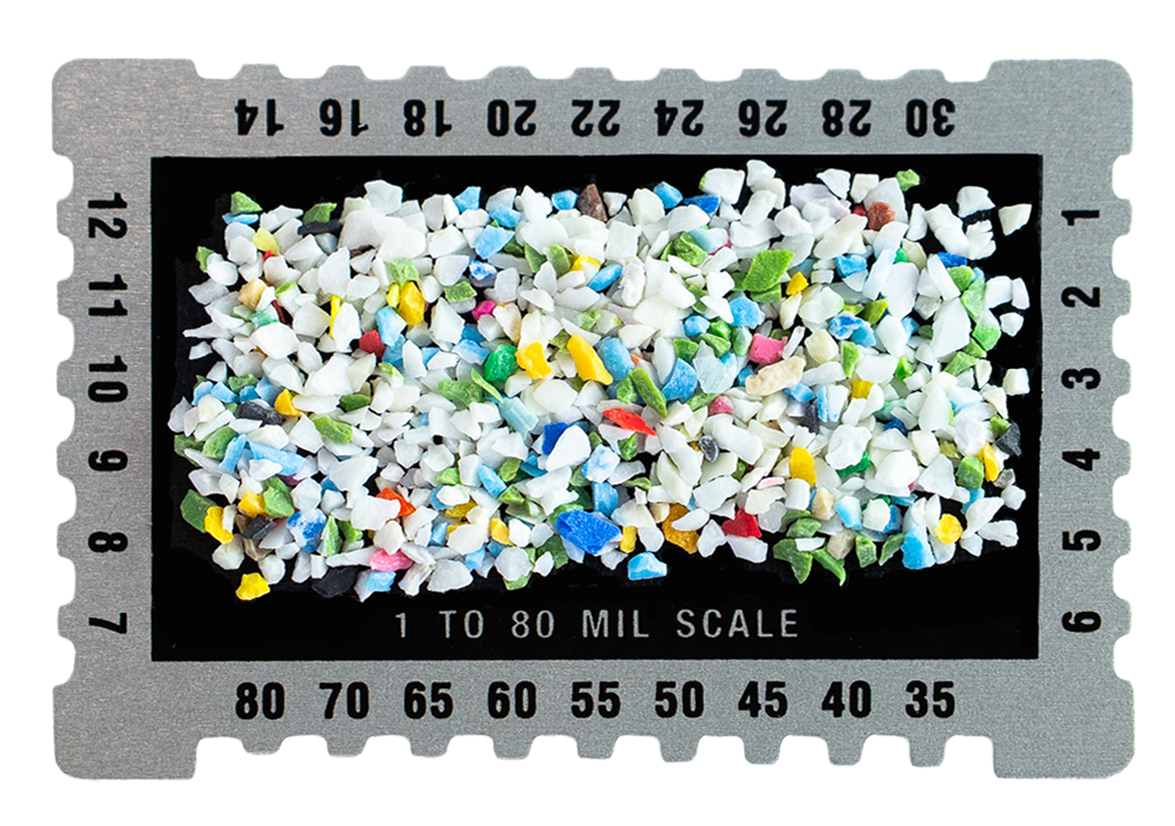

Types of Plastic Media Defined in MIL-P-85891A

Types of Plastic Media Defined in MIL-P-85891A

Type II — Urea Plastic Media

Type II is considered the standard for many aircraft maintenance operations.

Characteristics:

- Moderately hard

- Low aggressiveness

- Predictable stripping action

- Excellent protection of thin substrates

Typical uses:

- Aluminum aircraft skins

- Composite structures

- Delicate or thin-gauge parts

- General-purpose aviation stripping

It’s the go-to choice when technicians need tight control over the stripping process.

Type V — Acrylic Plastic Media

Type V is harder and more durable, offering a faster strip rate while still maintaining the substrate’s integrity.

Characteristics:

- Higher hardness

- Longer life cycle

- Clean, consistent cutting behavior

Typical uses:

- Powder coating removal

- Pultruded aluminum parts

- Fiberglass components

- Surfaces that demand productivity without sacrificing safety

Where precision and efficiency must coexist, Type V acrylic is often preferred.

MIL-SPEC vs. Non-Certified Plastic Media

Not all plastic media is created equal. Commercial-grade products may look similar, but MIL-P-85891A media undergoes strict testing to ensure:

- Verified hardness

- Accurate particle size

- Controlled fracture behavior

- Cleanliness and purity

- Repeatability across batches

- Documented production traceability

This level of oversight is essential in environments where quality and consistency are safety issues, not preferences.

Why MIL-P-85891A Still Matters

Even as new stripping technologies emerge, plastic media blasting remains indispensable for one reason: it removes coatings without damaging the part beneath. Aircraft still rely on materials that cannot tolerate aggressive abrasives, and maintenance standards remain as stringent as ever.

MIL-P-85891A guarantees that the media used in these processes is dependable, consistent, and engineered specifically for these sensitive applications.

Where to Buy MIL-P-85891A Media

MIL-P-85891A-compliant Type II Urea and Type V Acrylic plastic media are available through SandblastingMachines.com. We are a trusted supplier for military, commercial, and industrial blasting operations requiring certified media.

If your operation requires media that meets the same standard used across the U.S. military, don’t hesitate to contact us via phone, e-mail, or chat.

Conclusion

MIL-P-85891A ensures that plastic blast media performs with the precision, safety, and consistency required for military and aviation maintenance. It’s a specification built on decades of real-world demands, protecting both equipment and personnel by ensuring coatings can be removed without harming the underlying material.

Whether you’re maintaining a military aircraft or servicing a private plane, MIL-SPEC plastic media provides the level of performance and reliability these environments demand.