BLACK BEAUTY ABRASIVES Coal Slag QPL Approved for SSPC-AB1 and MIL-A-2262B (in Select Plants) and Passes 40CFR 261.24a (TCLP) & California Title 17 (CARB) from Harsco.

BLACK BEAUTY® Abrasives are the original coal slag grit in the marketplace, leading the industry for nearly 80 years within a variety of applications requiring efficient and safe surface preparation and industrial cleaning. Coal slag abrasives are considered to be the best value per square foot of cleaning and are used to remove thick surface coatings, rust, paint, and mill scale from various substances such as stainless steel. aluminum, concrete, brick, and wood.

Blastox® Additive for Lead Paint Abatement

For projects involving lead paint removal, BLACK BEAUTY® Abrasives can be paired with Blastox®, a dry, granular calcium silicate-based additive specifically designed for lead paint abatement. Blastox® is pre-blended with abrasive media and simplifies lead paint removal while stabilizing harmful lead particles. This one-step process helps ensure non-hazardous removal, meeting EPA and DOT standards.

Blastox® has been used to stabilize over 150 million square feet of lead-based paint and is approved by the Federal Highway Administration and most state DOTs. It’s a ready-to-use solution upon arrival at the job site, requiring no additional mixing or metering, thus reducing labor costs. After blasting, spent abrasive waste can be tested via TCLP to verify its classification as non-hazardous.

By adjusting pH, initiating chemical reactions, and encapsulating harmful substances, Blastox® complies with multiple standards including TCLP, MEP, SPLP, and freshwater leach tests, making it a reliable choice for lead paint abatement.

To learn more about Blastox® click here.

Key Features & Benefits:

BLACK BEAUTY® Abrasives Coal Slag is chemically inert (or non-reactive) and contain less than 1% free silica produced from 100% recycled glass, preserving substrate integrity and reducing health hazards from silica dust for an eco-conscious and overall safer alternative during your blasting operations.

Angular-shaped and sharp-edged particles make this Coal Slag very effective at cutting and removing tough surface contaminants, providing better surface profiling for coating adhesion. Coal Slag has a hardness of 6 to 7 on the Mohs scale, demonstrating incredible efficiency at cleaning and prepping contaminated surfaces quickly and adequately.

Product Grades:

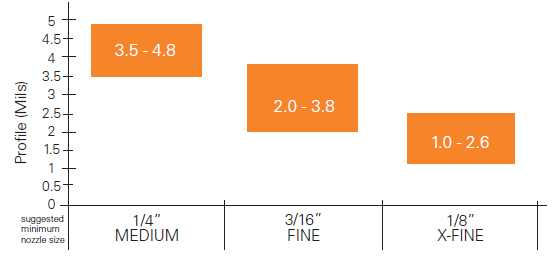

Medium: (12/30)

- Suitable for industrial applications, general purpose repair and maintenance blasting for the removal of paint, rust, structural steel, mill scale, and aggregate exposure (3.0-5.0 Mils).

- Suggested Minimum Nozzle Size of 1/8".

Fine: (20/40)

- For new construction, light paint, rust removal, and for special maintenance applications requiring reduced profiles. Automotive, hobby, and soda blast alternatives (2.0-3.5 Mils).

- Suggested Minimum Nozzle Size of 3/16".

Extra-Fine: (30/70)

- To clean surfaces and create a very smooth finish, brush-off blast, or in a high pressure water blast system. Ideal for a very low or specific profile (1.5-3.0 Mils).

- Suggested Minimum Nozzle Size of 1/4".

For any additional product information as well as storage and handling requirements, refer to the Product Data/Information Sheet or Safety Data Sheet provided in Manuals on this page.